Q.Which screed model should I choose for my Project?

Consider the following factors when determining which screed model is right for your project.

- Width of pour

- Slab thickness

- Slump of concrete

- Application

| Heavy-Duty | Cruiser | |

| Width | 5’ – 65’ | 5’ – 60’ |

| Slab Thickness | 8” – 18” | 6” – 12” |

| Slump | 3” + | 3” + |

| Residential – Slab | X | |

| Commercial – Slab | X | X |

| Streets / Highways | X | X |

| Airports / Heavy Civil | X | X |

Q.Which winching system is recommended?

The Speed Screed® Heavy-Duty™ and Speed Screed® Cruiser™ come standard with hand winches installed on each end of the screed. One-side hand winching is an inexpensive labor saving option for the Cruiser screed. Since winching screeds does not require a great amount of effort either one-sided or two-sided hand winching is most commonly chosen. However, when job specs for flatness and consistency are critical hydraulic winching helps provide smooth, consistent travel. Also, larger and longer screeds are usually purchased with the hydraulic option to reduce labor.

Q.Which size engine should I choose?

All MFC screeds come standard with Honda Engines. The Speed Screed® Cruiser™ comes standard with 5h.p engine. An 8h.p. engine upgrade should be chosen with hydraulic winching option or for screeds over 35’ in length. The Speed Screed® Heavy Duty™ comes standard with 8 h.p. engines. An 13 h.p. upgrade should be chosen with hydraulic winching option or for screeds over 30’ in length.

Q.What is optimum travel speed for properly placing concrete?

Optimum screed travel speed is 0-3 feet per min. Travel speed will vary depending on slump of concrete, thickness of slab and the number of people placing concrete in front of screed. Never allow screed to vibrate in place. This will cause aggregate separation and weaken finished product.

Q.What should I expect for slab consolidation?

View slab consolidation guidelines. Some factors affecting consolidation are: Screed travel speed / Size of aggregate / Slump of concrete.

Q. How much crown can I achieve with my screed?

There are a few terms you should be familiar with when adjusting crown.

- Parabolic Crown - Parabolic crowns are smooth & consistent arching crown across entire slab

- Roof Top Crown - Roof top crowns mean screed will have only one breakpoint, usually in center of slab/screed

- Inverted Parabolic Crown & Inverted Roof Top Crown - Inverted crowns means flow or pitch will be to center of slab. An ally would be a common use for inverted crown

Crowning achieved will be determined by the length of your screed and sections selected. The following is a guide using a 20' screed;

- Standard Rooftop 3”

- Standard Parabolic 6”

*Adding an EXTREME CROWN KIT will increase maximum crown achieved and capability for INVERTED CROWNING.

**Contact the MFC Sales Team to discuss your needs to ensure you order correct sections to achieve your crowning requirements.

Q.How do I determine length of sections I need to purchase?

The number of screed sections and the length of each section will determine crowning capabilities. The use of shorter screed sections (2-1/2 ft and 5 ft) will increase crowning capabilities. Longer screed sections should be used on wider slabs with little or no crown. The use of longer sections will help eliminate deflection at each joint.

Q.How many people will I need to rake / place concrete in front of screed?

There should be a minimum of one person per 10’ of screed raking or placing concrete in front of screed. A primary to a good finished product is to have placers monitoring concrete in front of screed never allowing holes or mounds in the concrete.

Q.What should I expect for daily rate of production?

Common daily production rates are 800-1,200 lineal feet per day.

Q.Lead-time - How long will it take for me to receive my screed?

To find out current lead-times, click HERE to e-mail our sales team or call the office direct at 414-964-4550 to speak with a sales person.

Q.How will my screed be shipped?

Most screeds will be shipped via a common carrier; semi/van type. The screed will be banded to a skid/pallet and shrink wrapped. All screed deliveries should be inspected upon receipt at customer’s facility. It will be necessary to have equipment available to offload the screed. Lifting equipment should have a minimum 2,000 pound lifting capacity.

Q.What assembly will be required when I receive my screed?

Screeds are shipped to provide customers with the least amount of set up. After removing packaging from screed you should be up and running in a matter of 30-60 minutes. All machines are shipped with an owner’s instruction manual Speed Screed® Heavy-Duty™ or Speed Screed® Cruiser™. All manuals are also available on our website.

Q.Owners Instruction Manuals - Speed Screed®

Click here to open your manual for the Speed Screed® Cruiser™: Owner’s Instruction Manual

Click here to open your manual for the Speed Screed® Heavy Duty™: Owner’s Instruction Manual

Q.Troubleshooting

Screed shaft won’t spin

- Is there too much tension on the set screws for the coupler? This could cause premature clutch failure.

- Can the shaft be turned by hand? If yes, check to see if the sheave and clutch are engaged by set screws and/or keyway. If no, loosen the set crew on the couplers to release tension in the shaft, then re-tighten the set-screws.

Inspect the belt for proper tension and/or possible fatigue.

Screed shaft won’t stop spinning

- Is the engine idling and the shaft still continues to spin? Could be the clutch has failed.

To check the clutch, remove the belt to see if the clutch spins freely by hand turning (while motor is off).

If the clutch doesn’t spin freely, the clutch should be replaced.

If the clutch does spin freely, check the belt for too much tension.

Winch won’t turn (Hydraulic Screeds only)

- First Checks: With the screed engine running (full throttle), visually check that the shaft is spinning, the winch spool knob is engaged, and the flow control knob is fully turned clockwise to max speed.

- Is the screed shaft spinning? If no, check the clutch or check the belt tension (see above). If yes, is the lovejoy/spyder connection spinning? If no, replace the lovejoy/spyder connection. If yes, is the disconnect knob engaged in the winch? If no, engage the knob. If yes, remove the disconnect knob and unwind the spool.

- Is the spool engaged to the winch spool shaft? If no, check that the set screw for the spool shaft is engaged in the hydraulic motor keyway slot by removing the winch spool.

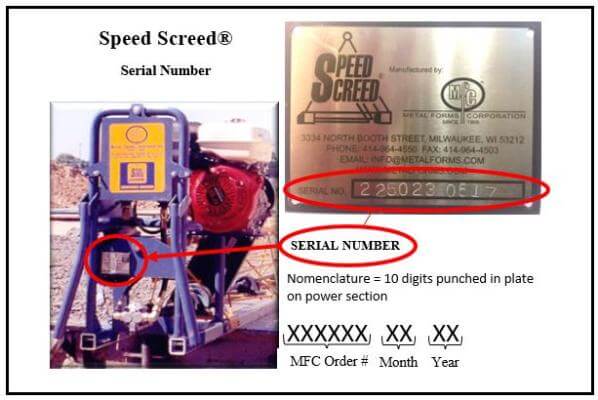

Q.Serial Number Explanation (Need when calling to discuss)

MFC Speed Screed® will always be identified with a Serial Number. The S/N will be punched in a metal plate located on the power section of the screed. When calling MFC to discuss your screed, you should have your serial number handy so we can identify the model. This is critical in determining replacement/additional parts you may require.

Q.Where can I find a parts list?

Speed Screed® Owners Manuals contain parts list/parts breakdown

Q.What type of hydraulic oil should I use?

DTE 26 - Hydraulic Oil

Q.How can I clean & maintain my screed?

- The screed should be sprayed with form release agent prior to each use

- Clean up should be done with a water hose and brush

***WARNING - Use of a pressure washer may remove paint

Q.What are Skis and where should I put them?

- Ski assemblies are provided on all screeds. However, they are not necessary unless you want to allow a small amount of concrete to flow under the front tube.

- They are to be used on the front tube only. They can be removed it too much concrete accumulates in front of rear tube.

Q.How should I move my screed around a job site?

- Each section comes standard with a welded lifting bracket

- Fully assembled screeds should never be lifted in the center, instead they should be lifted near each end frame section.

Q.When/how do I rotate my aluminum tubes?

- The design of the finishing tubes provide a double life wearing surface

- Most screeds will wear more near the end frame where they ride on the slab or formwork

- When the wall thickness of the tube nears 1/16" the tube can be rotated by removing the bolts and rotating the tubes 180 degrees.

Q.What is the warranty on my screed?

- Honda Warranty - Your local Honda dealer can assist with warranty issues should they arise with your engine. MFC does not hold a warranty on the Honda Engine.

- Manufacture Warranty - MFC has a 90 day limited warranty. See owners manual for details

Q.How much overhang do I need beyond the width of the slab?

- A minimum of 6" on each end is recommended.

- No more than 18" is recommended or damage may occur.